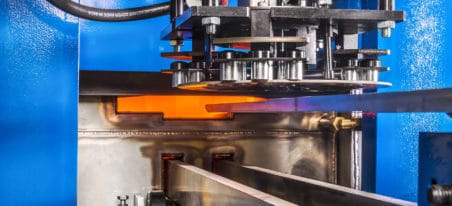

The ICBP range is made of modular installations dedicated to quenching, low pressure / vacuum carburizing and low pressure carbonitriding. However, these flexible and scalable installations can integrate different processes within the same line.

For more than 25 years, ECM Technologies has been a reference for main contractors with its patented Infracarb® process and its range of modular ICBP® installations.

To meet the most diverse applications, the ICBP® range is now available in modular furnaces, such as:

ICBP® Flex – Multi chamber and modular installation for vacuum carburizing

ICBP® Jumbo – Multi chamber and scalable installation for larger volumes

ICBP®Duo – Double chamber furnace for vacuum carburizing and quenching applications

ICBP® Mono – Single chamber furnace adapted to aeronautic applications

ICBP® Nano – Highly integrable and compact vacuum carburizing system

PFTH – Vertical oil quenching installation for large loads

More than 335 installations corresponding to more than 1652 vacuum carburizing cells are producing in the world today.

These aforementioned ICBP installations stand for the French acronym “Installations de Cémentation Basse Pression”, which means Low Pressure Carburizing Installations. However, these machines can handle many more processes. Indeed, LPCN (Low Pressure Carbonitriding), brazing, sintering and many kinds of quenching can take place within these lines. Furthermore, all of ECM Technologies ICBP installations can reach a high level of automation and can be set up directly in workshops. As an example, the ICBP Nano can be considered as a machine tool for vacuum carburizing since it can be fully integrated into production lines.

Another advantage of the ECM Technologies’ range of LPC installations lies in the fact that these machines can be integrated directly into factories. This is mainly due thanks to the use of vacuum. No flames result from carburizing or quenching operations. Also, the cold wall technology ensures great working conditions for operators since no heat is generated outside the furnace.

Today, an in line clean heat treatment is finally possible.